growth opportunities emerging through digitalization and connectivity.

1. The Evolution of Manufacturing Technologies: Industry 5.0

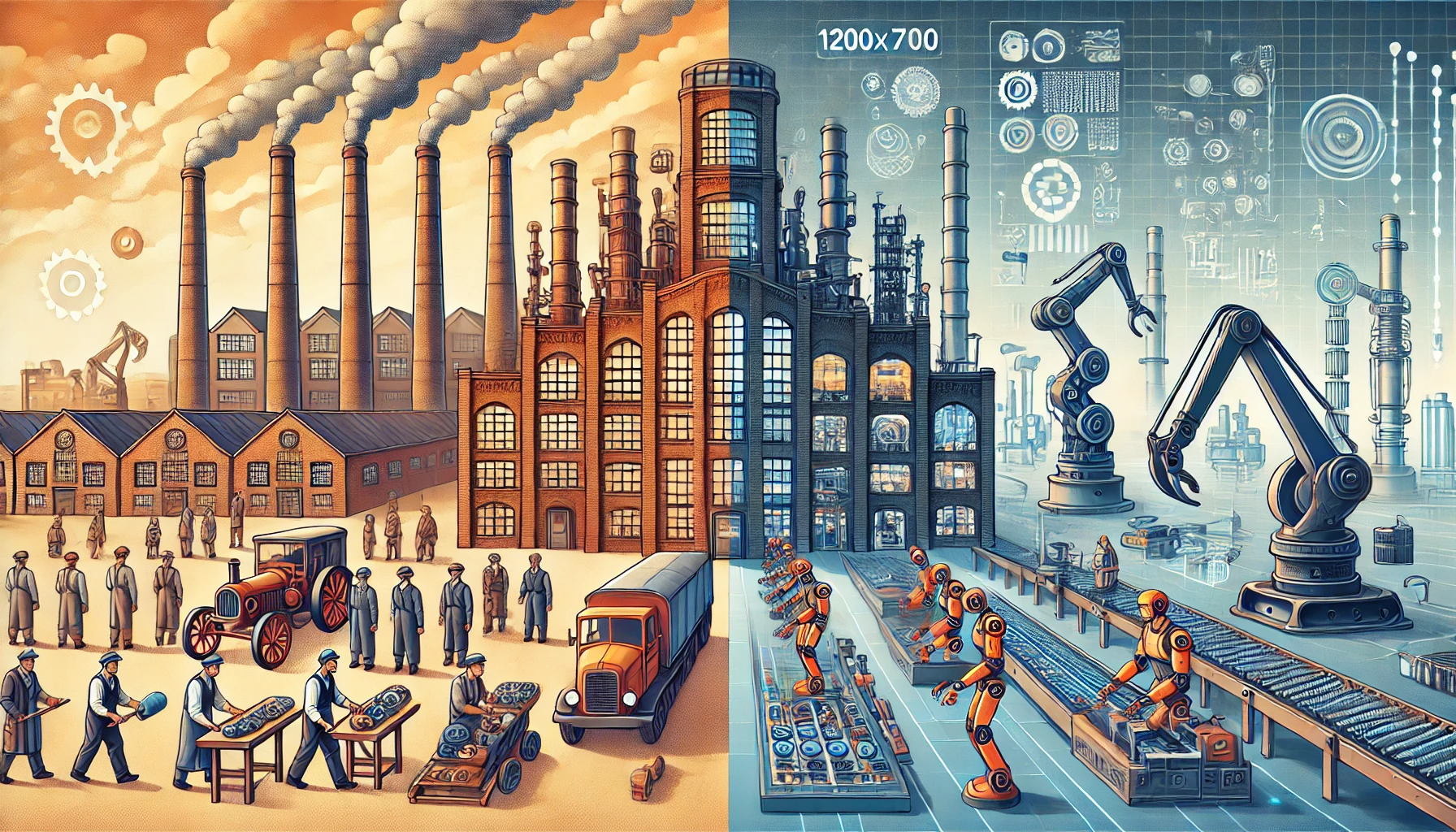

Manufacturing has undergone multiple revolutions. From the mechanization of the First Industrial Revolution to the digital automation of Industry 4.0, the focus has shifted from traditional methods to the adoption of advanced technologies. Industry 5.0 is set to take manufacturing to new heights by integrating human creativity and precision with cutting-edge machines and AI systems.

Industry 5.0 is centered around human-centric manufacturing, where the collaboration between humans and intelligent machines drives innovation. Unlike Industry 4.0, which focused mainly on automation, Industry 5.0 emphasizes the augmentation of human skills through machines that support human decisions and actions rather than replacing them.

The key differentiator of Industry 5.0 is its focus on personalization and customization, enabling manufacturers to meet the ever-changing demands of consumers. It’s a more sustainable approach, where human intelligence and creativity lead to greater innovation, and machines enable us to bring these ideas to life more efficiently.

2. Future Growth and Opportunities in the Indian Manufacturing Sector

India’s manufacturing industry is poised for significant growth in the coming years. With the Indian government’s "Make in India" initiative and a renewed focus on digital transformation, Industry 5.0 presents new avenues for growth, enhancing production capabilities, reducing costs, and driving innovation.

- Increasing Production Capacity: As Indian manufacturers adopt Industry 5.0 technologies, they will be able to scale production rapidly, providing better products at competitive prices.

- Customization and Personalization: Industry 5.0 opens up the ability to mass-produce personalized and customized products for consumers, which is especially important in markets like India, where consumer preferences are diverse.

- Sustainability and Efficiency: By leveraging AI, IoT, and automation, Indian manufacturers can reduce waste, optimize energy consumption, and produce goods more sustainably, aligning with global sustainability goals.

Industry 5.0 will allow Indian manufacturers to differentiate themselves in both domestic and international markets. This transformation will foster growth by increasing productivity, enabling greater customization, and enhancing workforce capabilities.

3. The Transformative Impact of Digitalization and Connectivity

At the heart of Industry 5.0 lies digitalization and connectivity. The integration of digital tools and platforms will transform manufacturing into a more transparent, efficient, and responsive process. Here’s how digitalization is reshaping the Indian manufacturing landscape:

- Smart Factories and Real-Time Monitoring: The rise of smart factories enabled by IoT and real-time data analytics will allow manufacturers to track machine performance, inventory, and production metrics continuously. This leads to increased operational efficiency and quick decision-making.

- Supply Chain Integration: Advanced connectivity allows manufacturers to have a clearer view of their supply chain, leading to better inventory management, reduced lead times, and more accurate forecasting. Indian manufacturers can now build more resilient and flexible supply chains in the face of global disruptions.

- Cloud-Based Platforms: Cloud computing platforms will allow for better collaboration, data storage, and remote access, enabling manufacturers to innovate, optimize processes, and scale operations without being bound by physical locations.

By integrating advanced technologies with digital platforms, India’s manufacturing sector can streamline operations, create real-time solutions, and position itself as a leader in the global market.

4. Exploring the Roles of AI, ML, IoT, and Automation in Manufacturing

A critical component of Industry 5.0 is the seamless integration of artificial intelligence (AI), machine learning (ML), the Internet of Things (IoT), and automation in manufacturing processes. These technologies are not just transforming operations—they are enabling entirely new ways of designing, producing, and distributing goods.

- AI and Machine Learning: AI and ML are enabling predictive maintenance, quality control, and process optimization. By analyzing data from machines and production lines, these technologies can predict potential failures, reducing downtime and ensuring smoother operations. ML algorithms also optimize production schedules based on real-time demand and market conditions, ensuring that manufacturers stay agile and responsive.

- IoT: IoT connects machines, devices, and systems, providing manufacturers with real-time data that enhances operational visibility and decision-making. With connected devices, manufacturers can monitor every stage of production, detect inefficiencies, and adjust processes instantly, leading to enhanced productivity and minimal disruptions.

- Automation: Automation is the backbone of Industry 5.0, combining robotics and AI to optimize production lines, reduce human error, and ensure faster production cycles. Automation technologies allow for more precise and cost-effective manufacturing, whether it’s high-volume, repetitive tasks or intricate, customized production needs.

5. Key Trends Shaping the Future of Indian Manufacturing

The rise of Industry 5.0 in India is driven by several transformative trends that are set to shape the future of manufacturing in the country:

- Customization at Scale: Customers today expect personalized products tailored to their preferences. With Industry 5.0 technologies, manufacturers will be able to produce highly customized goods without sacrificing efficiency or increasing costs. AI-driven design and 3D printing will play crucial roles in making this happen.

- Sustainability Initiatives: As India becomes more conscious of sustainability, Industry 5.0 will help manufacturers reduce their environmental footprint. Digital twins, AI optimization, and real-time data analytics will help track and minimize waste, reduce energy consumption, and enhance sustainable production processes.

- Collaborative Robotics (Cobots): Unlike traditional industrial robots, collaborative robots (cobots) work alongside humans on the production floor. These robots can assist workers with physical tasks, allowing humans to focus on more complex or creative tasks. This will increase the overall productivity of Indian manufacturers while improving worker safety.

- Edge Computing and Real-Time Data: Edge computing allows manufacturers to process data closer to the source, reducing latency and improving the efficiency of real-time decisions. This is crucial for applications like predictive maintenance and supply chain management, where immediate insights are critical.

Conclusion

Industry 5.0 is ushering in a new era of manufacturing that goes beyond automation to integrate human ingenuity with cutting-edge technologies. For the Indian manufacturing sector, the opportunities are immense, from improving production efficiency to embracing sustainability and driving customization. By embracing Industry 5.0 technologies like AI, IoT, automation, and ML, India’s manufacturers can not only overcome challenges but also create new avenues for growth and innovation.

As digitalization and connectivity continue to redefine manufacturing, Indian companies that invest in these technologies will be better equipped to compete on a global scale, meet the needs of consumers, and drive the future of manufacturing forward.