Industry 5.0 is changing the manufacturing landscape, and how businesses can capitalize on this human-centric model to stay competitive and drive innovation.

1. What is Industry 5.0?

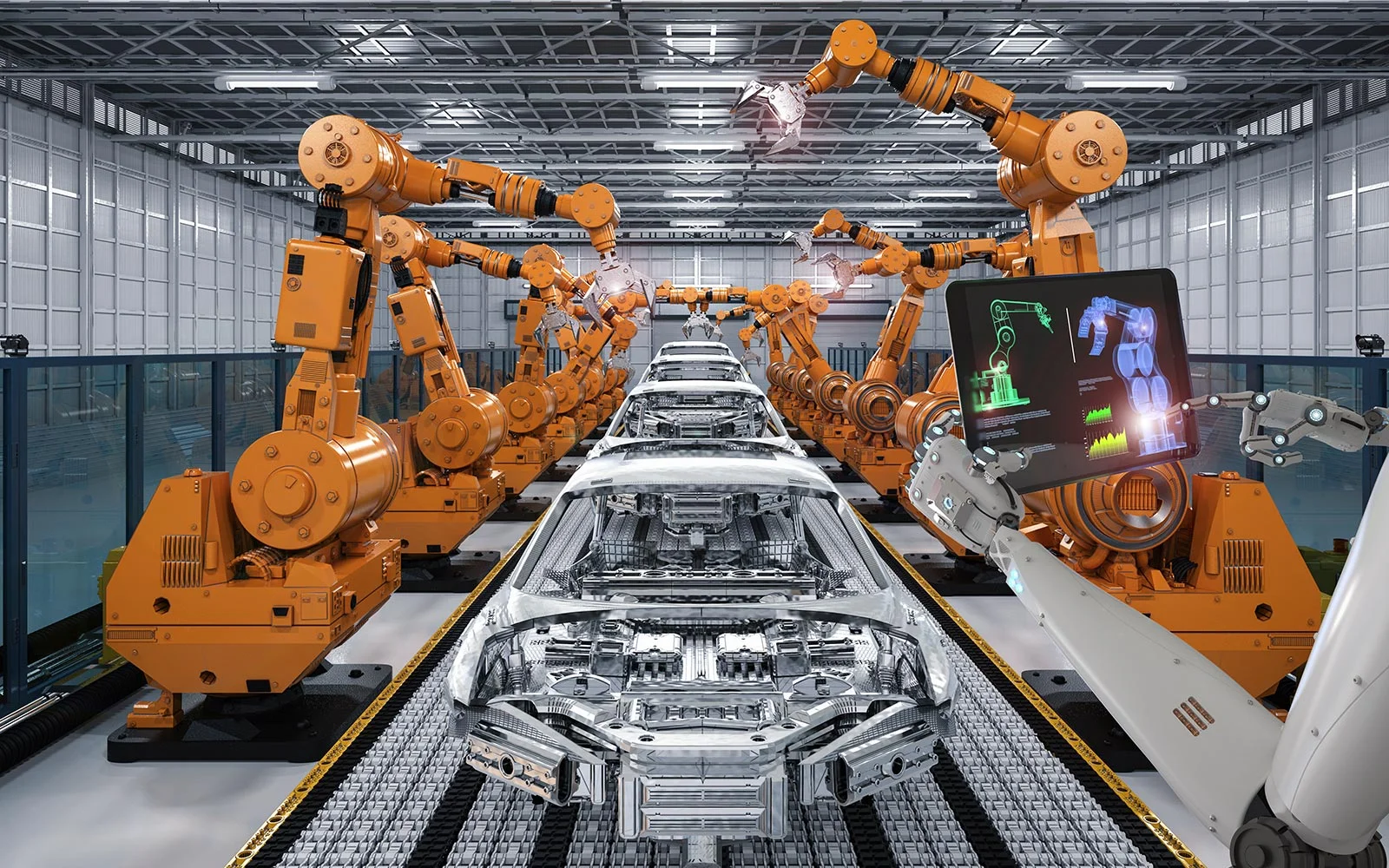

While Industry 4.0 focused on automation, data exchange, and cyber-physical systems, Industry 5.0 takes a more human-centric approach. It emphasizes collaboration between humans and advanced technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT). In essence, Industry 5.0 brings human intelligence, creativity, and emotional understanding back into the manufacturing process.

At its core, Industry 5.0 aims to create systems where machines handle repetitive tasks, and humans focus on more complex, creative, and decision-making responsibilities. This model combines the strengths of both human workers and robots, leading to a more flexible, adaptive, and personalized approach to manufacturing.

2. Human-Machine Collaboration: The Heart of Industry 5.0

One of the most significant shifts that Industry 5.0 brings is the evolution of collaborative robots, or cobots. Unlike traditional robots, which were designed to replace human workers, cobots are built to work alongside humans, assisting in tasks that require precision, strength, or repetitive action.

In this collaborative environment, workers are freed from physically demanding or mundane tasks and can focus on activities that require creativity, problem-solving, and decision-making. Cobots, with their ability to learn from human behavior, can adapt to the needs of the task at hand, increasing productivity and reducing the risk of human error.

This collaboration is particularly beneficial in industries like automotive manufacturing, electronics, and food production, where precision, flexibility, and customization are essential. As machines take on the repetitive and tedious aspects of production, humans can add value by focusing on innovation, quality control, and customer-centric designs.

3. Personalization and Customization at Scale

One of the key promises of Industry 5.0 is hyper-personalization in manufacturing. In the past, mass production meant that products were standardized, with little room for customization. But with advances in technology, consumers are now demanding more personalized products tailored to their individual needs.

Industry 5.0 enables the seamless integration of customization with mass production. Through AI, advanced robotics, and flexible manufacturing systems, businesses can offer customized products at scale, whether it’s personalized clothing, furniture, or even vehicle designs.

This shift is not only about meeting customer demands but also enhancing the overall customer experience. Manufacturers who embrace hyper-personalization can create more loyal customers, differentiate themselves from competitors, and tap into new markets.

4. Smart Manufacturing: Data-Driven Decision Making

Industry 5.0 takes the concept of smart manufacturing to the next level by integrating advanced data analytics and AI into the production process. This allows manufacturers to gain deeper insights into their operations, improving everything from supply chain management to quality control.

Through AI-powered systems, manufacturers can collect and analyze real-time data from every stage of production. This data-driven approach allows for predictive maintenance, reducing downtime and improving overall efficiency. By leveraging insights from data, manufacturers can also optimize their operations, reduce waste, and minimize costs.

Moreover, AI can help manufacturers respond to changing market demands quickly and effectively, ensuring that production schedules are aligned with consumer needs and external factors like supply chain disruptions or material shortages.

5. Sustainability and Ethical Manufacturing

Industry 5.0 is also pushing the boundaries of sustainability in manufacturing. While Industry 4.0 introduced energy-efficient technologies and waste reduction methods, Industry 5.0 takes it further by focusing on ethical practices and environmental impact. With consumers increasingly prioritizing sustainability, manufacturers are under pressure to adopt green practices that go beyond energy savings.

Industry 5.0 encourages the use of sustainable materials, renewable energy sources, and environmentally friendly production methods. Moreover, it promotes the adoption of a circular economy, where products are designed for reuse, recycling, and long-term sustainability. By integrating these practices into their operations, manufacturers can reduce their carbon footprint, lower waste, and contribute to a more sustainable future.

6. The Role of Artificial Intelligence in Industry 5.0

Artificial intelligence plays a central role in the transformation of manufacturing under Industry 5.0. AI technologies are enhancing various aspects of production, from design to assembly, and even customer interactions.

For example, AI-powered design tools enable manufacturers to create highly customized products by analyzing customer preferences and predicting trends. In the production process, AI can optimize workflows, ensure quality control, and minimize waste through predictive analytics and process optimization.

Additionally, AI helps manufacturers improve employee safety by monitoring working conditions in real-time, detecting potential hazards, and offering insights to prevent accidents before they happen. This creates a safer and more efficient workplace where human and machine collaboration thrives.

7. The Future Workforce: Reskilling and Collaboration

As Industry 5.0 places more emphasis on human-machine collaboration, there’s a growing need for workers with advanced skills in technology and innovation. While automation and AI will handle repetitive tasks, skilled workers will continue to play a critical role in the decision-making, strategic planning, and problem-solving aspects of manufacturing.

Manufacturers will need to invest in reskilling and upskilling programs to ensure their workforce is equipped to handle these advanced technologies. Providing training in areas like robotics, data analysis, and AI will not only increase productivity but also create a more adaptable workforce capable of driving innovation.

Moreover, as more people embrace flexible work arrangements and remote monitoring, the role of the traditional factory worker will evolve. The workforce of the future will need to be agile, innovative, and tech-savvy to thrive in this new, interconnected world.

8. Adopting Industry 5.0: A Roadmap for Manufacturers

Transitioning to Industry 5.0 may seem daunting, but it offers significant opportunities for growth and innovation. Here’s a roadmap for manufacturers looking to embrace this new era:

- Start with Human-Centric Solutions: Begin by introducing cobots and enhancing collaboration between humans and machines. Identify tasks that can be automated and those that benefit from human expertise.

- Leverage Data and AI: Invest in data-driven solutions, including predictive analytics, AI-powered decision-making tools, and digital twins, to optimize production and improve efficiency.

- Prioritize Sustainability: Adopt eco-friendly practices, renewable energy, and sustainable materials in your production processes. Align your business practices with the growing demand for ethical and environmentally responsible products.

- Reskill Your Workforce: Invest in training programs to equip your employees with the skills needed to work alongside advanced technologies. A skilled workforce is the key to unlocking the full potential of Industry 5.0.

Conclusion

Industry 5.0 is revolutionizing manufacturing by combining human ingenuity with the power of advanced technology. By embracing this human-centric approach, manufacturers can enhance productivity, drive innovation, and deliver highly personalized products—all while maintaining a focus on sustainability and ethical practices.

The future of manufacturing lies in creating systems that leverage the strengths of both humans and machines. Those who embrace Industry 5.0 will not only thrive in an increasingly competitive global market but also shape the future of an industry that continues to innovate and evolve.